The Skilhunt H150 is recalled due to a short circuit

See my previous post on the subject for details. If you have an H150 ordered before August 2023, I recommend contacting the manufacturer to arrange a return and replacement with a corrected model.

As Skilhunt did not request the return of my review sample, I decided to take it apart and see what's inside, and maybe get something more out of it than a v3 clip for my M150 v2. I do not recommend attempting to repair a recalled headlamp; this post is for educational purposes only.

Disassembly

Like most Skilhunt lights, the H150 has permanent threadlocker on the head side of the battery tube. A pair of strap wrenches made unscrewing the head to access the driver easy.

The bezels for the switch and optic unscrew easily.

The charging pad's bezel also unscrews, but it's potted and I didn't try to access its components.

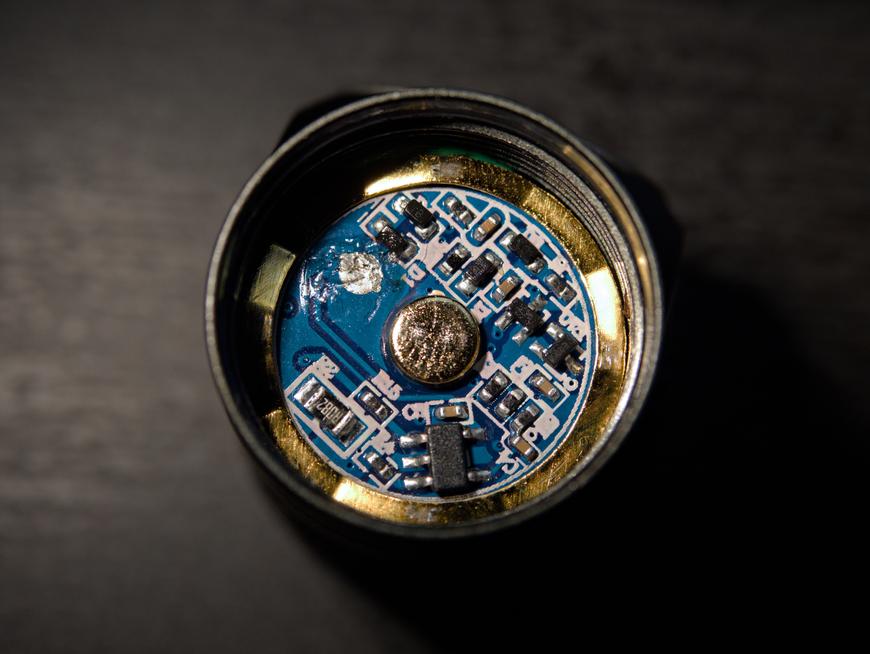

The driver is fairly compact, and has nine wires connected; this light has a lot of functionality packed into a small head.

The reverse polarity protection pin is clearly attached to a large trace area that goes all the way to the ground ring. That's the short circuit.

RPP is a good idea, but burning out a driver is a far better outcome than a dead short and risk of explosion in a headlamp. A bit of heat and a bit of superglue should make this a whole lot safer.

This springy ring on the driver isn't for retention, which explains the use of threadlocker. It should be impossible for a battery contact to touch the pad where the RPP pin was attached. The cured superglue provides an extra safety margin.

I probably shouldn't, but....

Nothing melted, let the smoke out, or exploded. I'm still not going to put this in my pocket or on my head with an unprotected Li-ion in it.

Comments

You can use your Mastodon or Lemmy account to reply to this

Reply Reply

Reply

Loading...